| Home | Gallery | Emergency Help | Contact Us |

|

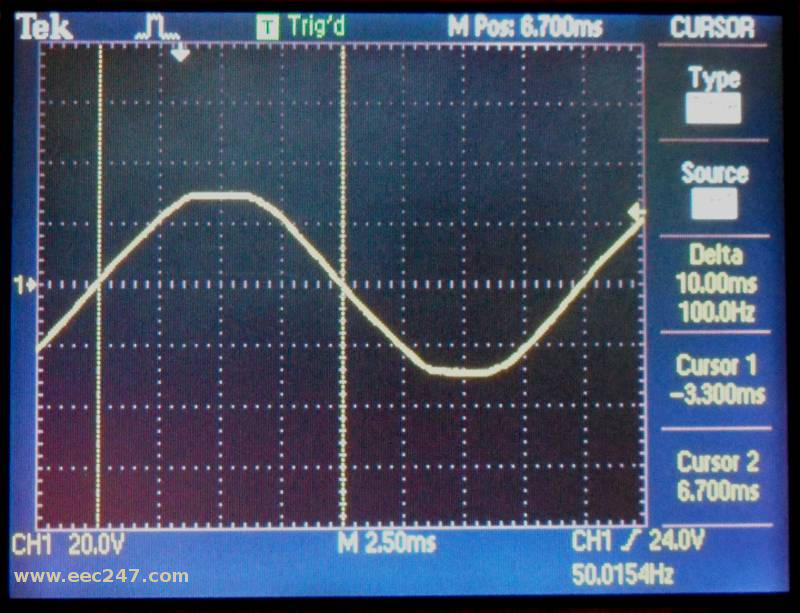

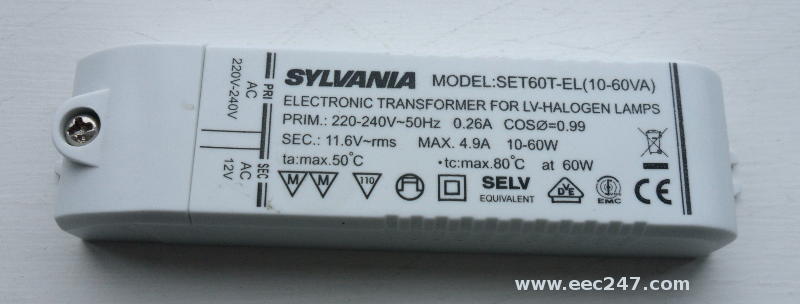

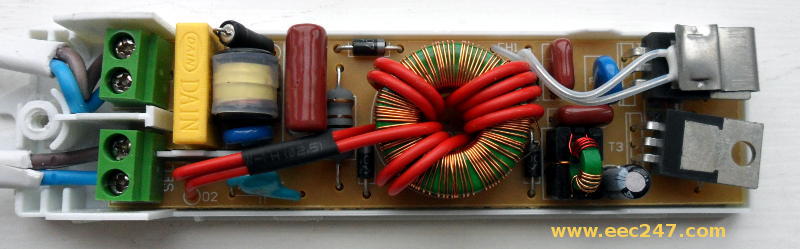

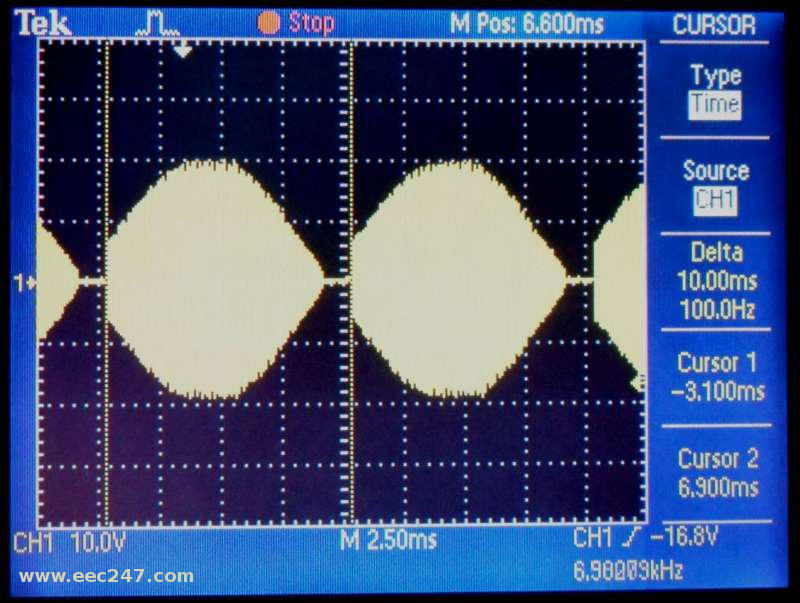

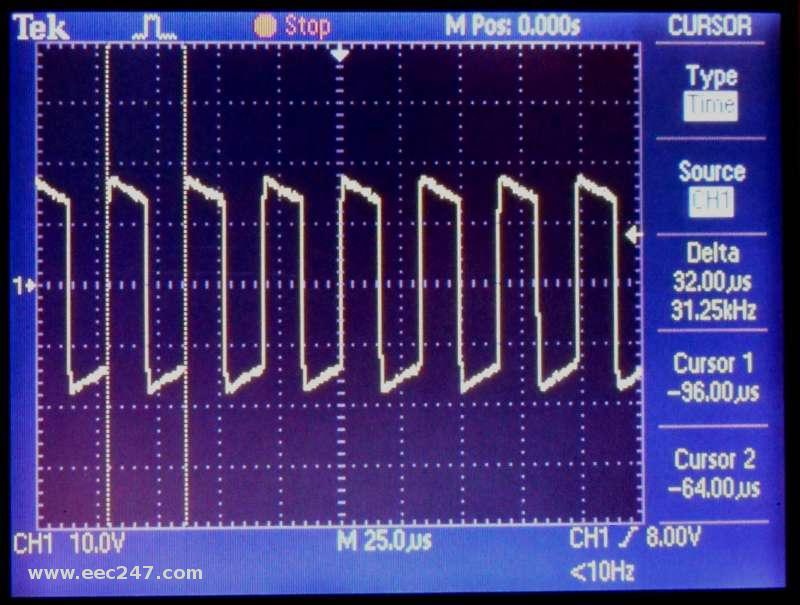

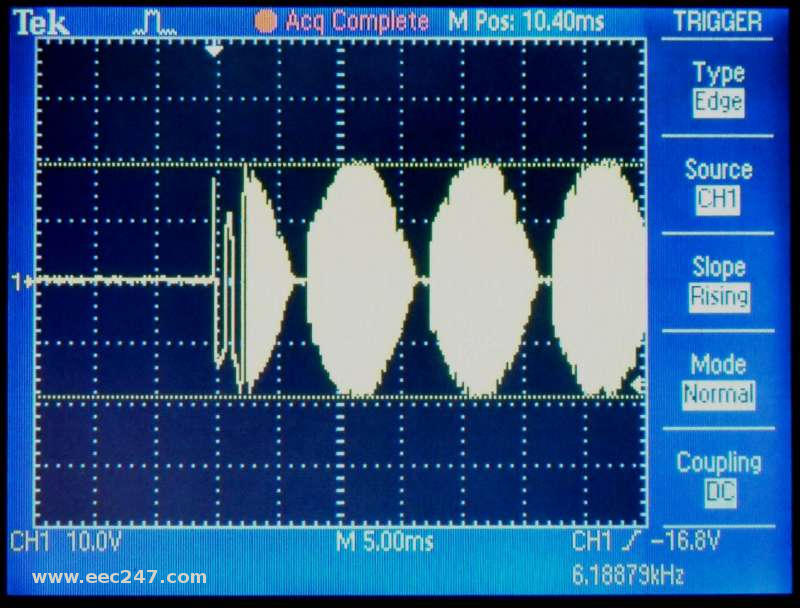

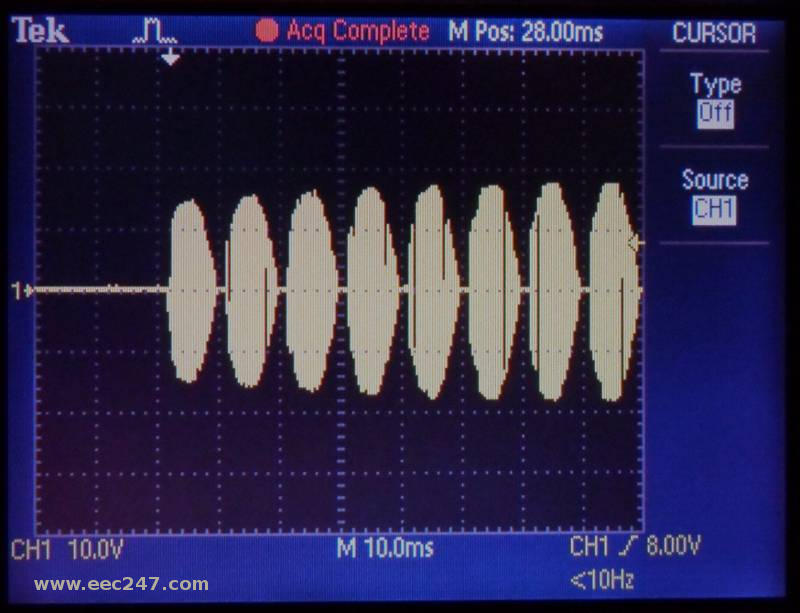

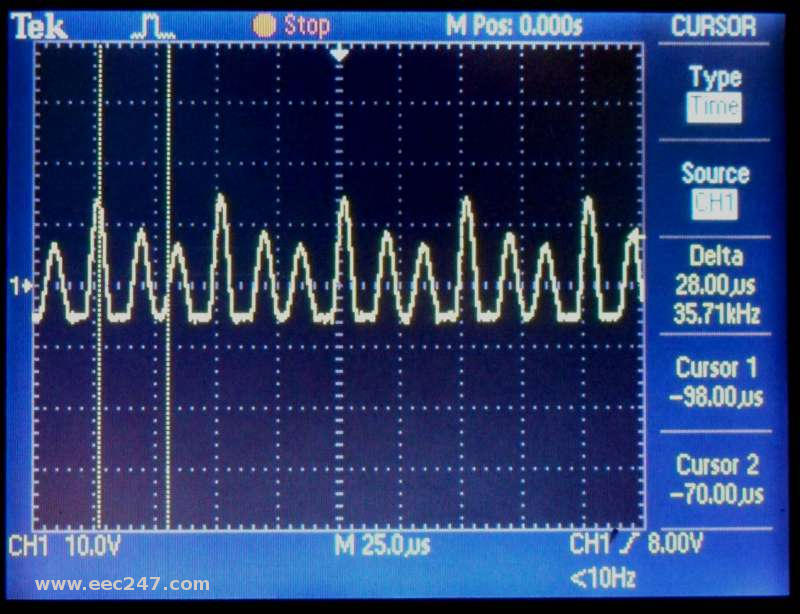

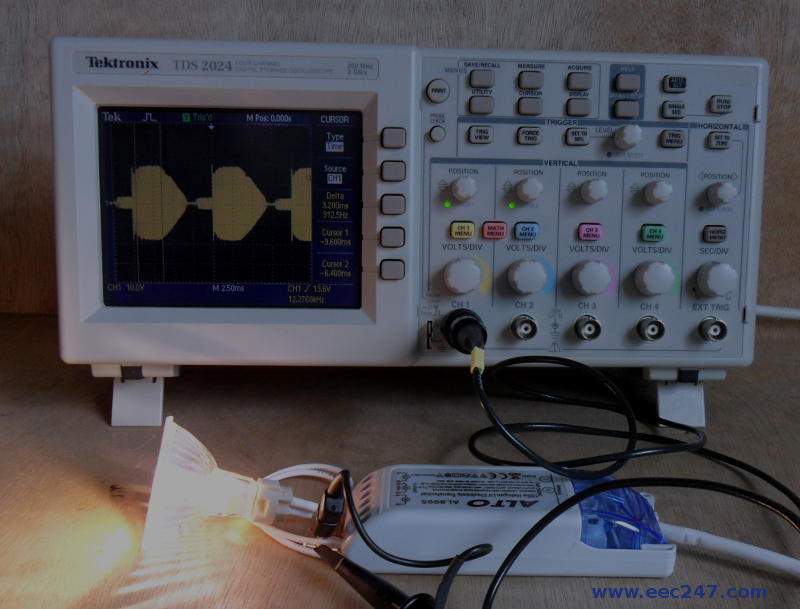

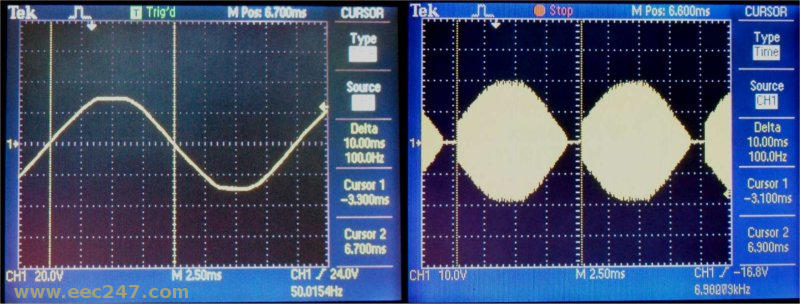

Conventional (non electronic) Transformers Conventional soft steel laminated core transformers consist of a primary winding connected to the mains supply (230 Volts) and a secondary winding, with a 12 Volt output connected to the load. There are a number of methods for keeping the primary and secondary windings separated. The type of interest here is SELV (Separated Extra Low Voltage) as still used in shaver outlets and used for halogen downlighters until the late 1990s. Modern (electronic) Transformers Modern electronic transformers use switched mode power supply type technology as used in Personal Computers since the early 1980s. Basically the mains voltage is chopped at high frequency and fed through a toroidal (doughnut shaped) transformer made from high density iron. As the frequencies are much higher than mains frequency, the transformer cores can be smaller, lighter and less complicated to make than conventional transformers. Modern electronic components are also cheap and plentiful. All things considered, modern electronic transformers are smaller, lighter and cheaper to manufacture than conventional transformers. |